Pre-Engineered Metal Buildings are steel buildings in which excess steel is avoided by tapering the sections as per the bending moment required. The design of the building is done by a qualified engineering team which ensures that the design of the building is optimum, after this all the components are pre-fabricated in a manufacturing facility with modern equipment. Finally, these components are transported to the site, and erection is done using nuts & bolts.

Pre Engineered Metal Buildings are steel buildings in which excess steel is avoided by tapering the sections as per the bending moment required. The design of the building is done by a qualified engineering team which ensures that the design of the building is optimum, after this all the components are pre-fabricated in a manufacturing facility with modern equipment. Finally, these components are transported to the site, and erection is done using nuts & bolts.

The concept of PEBs came into existence during the 1960s in the USA in order to erase construction complexities and save time & resources. The core of PEB as a technology lies in providing the sections at a location as per the requirement at that particular spot. The sections may be varying throughout the length according to the bending moment diagram.

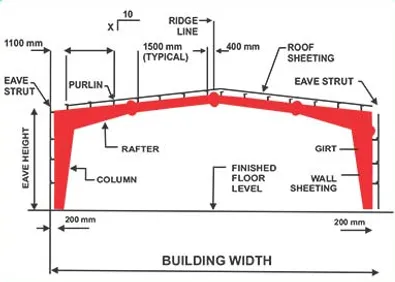

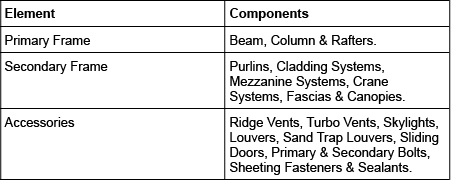

This leads to the utilization of slender elements instead of non-prismatic rigid frames. Tapered I-sections made with built-up thin plates are used along with Standard hot-rolled sections, cold-formed sections, profiled roofing sheets, etc to achieve the desired configuration. This results in an optimum structure saving your cost, time & resources. A typical Pre Engineered Building primary frame is shown below.

Years of experience

Happy Clients

Business Partners

Projects Done